Industrial First Aid Kits: CPR & AED Emergency Supplies for Manufacturing Companies

TLDR;

Industrial

first aid kits for manufacturing companies must include CPR and AED emergency supplies to meet OSHA and ANSI standards while protecting workers in high-risk environments. These kits go beyond basic supplies by equipping teams with tools for cardiac arrest, trauma, burns, and serious injuries. At Rapid Rescue Kits, we provide traditional emergency response kits designed to help stabilize injuries and support effective action until professional medical care is available.

Why Industrial First Aid Kits Matter in Manufacturing

Manufacturing environments present higher risks than office or retail settings. Heavy machinery, sharp tools, chemicals, and high-voltage equipment create hazards where accidents can quickly escalate. Having industrial first aid kits that include CPR and AED equipment supports an immediate response when every second matters.

Workplace safety culture depends on preparedness. When employees know that emergency supplies are accessible, it builds confidence and reduces hesitation during critical events. Manufacturing facilities that prioritize first aid readiness show commitment to both compliance and worker wellbeing.

An industrial first aid kit is not just about minor cuts and scrapes. It must address:

- Severe bleeding

- Burns and chemical exposure

- Fractures or crush injuries

- Cardiac arrest

- Respiratory distress

Without proper emergency supplies, even small delays in response can affect outcomes.

OSHA First Aid Compliance in Manufacturing

OSHA requires employers to provide adequate first aid supplies for employees under regulation 29 CFR 1910.151(b). While the rule does not list exact items, it mandates that supplies must be appropriate to the hazards of the workplace.

For manufacturing companies, this means going beyond a basic wall-mounted first aid box. Industrial operations often involve higher risks, so compliance demands expanded supplies that can stabilize serious injuries until medical professionals arrive.

Key OSHA compliance points:

- Kits must be accessible and visible to employees

- Supplies must match potential hazards in the environment

- Designated personnel should be trained in first aid, CPR, and AED use

- Kits should be inspected regularly and restocked as needed

Failure to maintain adequate first aid supplies can result in penalties, but more importantly, it can leave employees unprotected during emergencies.

ANSI/ISEA Z308.1 Standards for Industrial First Aid Kits

The ANSI/ISEA Z308.1 standard provides clear guidance on the minimum requirements for workplace first aid kits. For manufacturing environments, Class B kits are typically recommended.

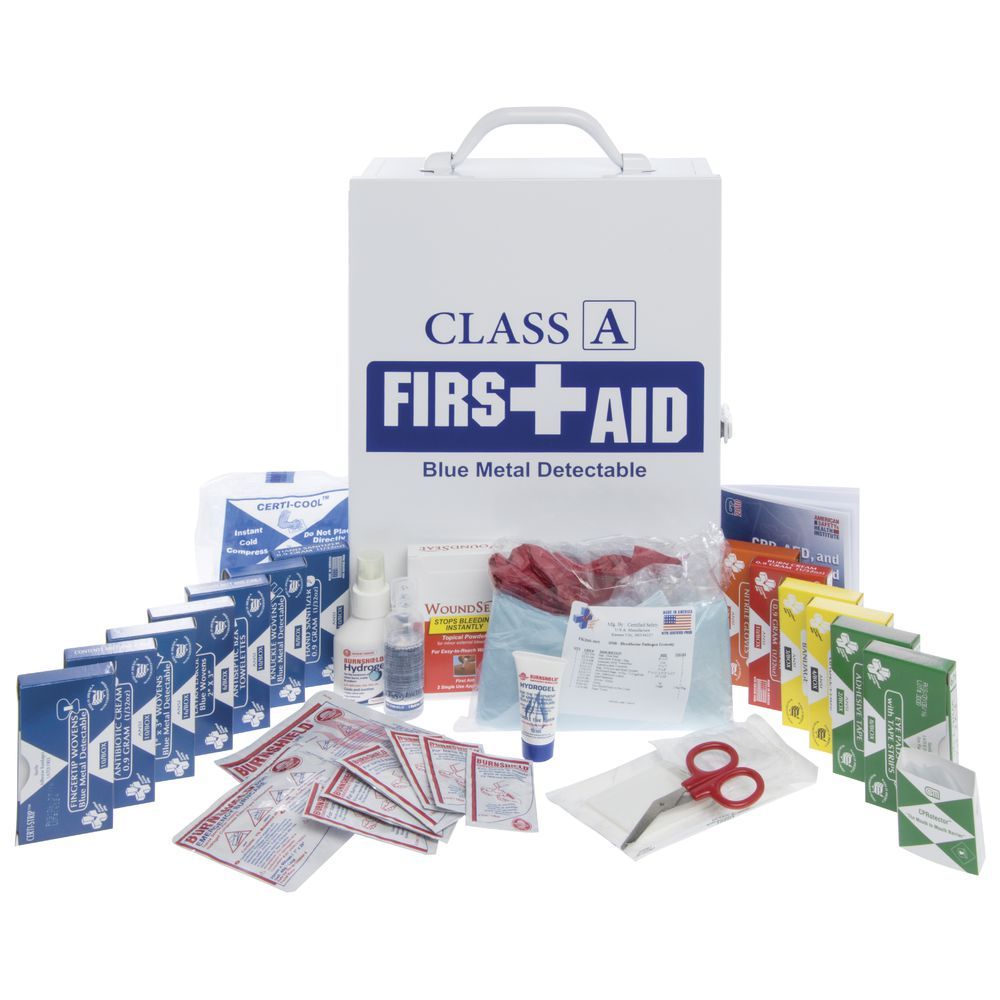

Class A Kits

- Intended for common workplace injuries like minor cuts, abrasions, or sprains

- Best for low-risk environments

Class B Kits

- Designed for high-risk settings such as factories, construction sites, and warehouses

- Contain a broader range of supplies for severe injuries

- Often required in manufacturing due to higher hazard levels

If your operations span across different industrial sectors, including construction, it’s critical to ensure consistency in emergency preparedness. The same standards that govern industrial kits in manufacturing also apply to

first aid kits for construction, where high-risk tasks demand immediate access to CPR and AED equipment. These parallels make it easier to standardize safety protocols across worksites.

Essential Contents of Industrial First Aid Kits

Standard Contents (ANSI Class A & B)

A compliant industrial first aid kit typically includes:

- Adhesive bandages of various sizes

- Sterile gauze pads and dressings

- Rolled gauze and adhesive tape

- Antiseptic wipes and antibiotic ointments

- Eye wash solutions

- Burn cream and cold packs

- Scissors and tweezers

- Non-latex gloves

These items cover common and moderate workplace injuries.

Critical Additions: CPR & AED Equipment

For manufacturing companies, CPR and AED supplies are essential. Sudden cardiac arrest can strike without warning, and rapid response is critical.

Essential CPR and AED additions include:

- CPR barrier mask with one-way valve

- Automated External Defibrillator (AED) device

- AED signage and wall cabinet for visibility

- Spare AED pads and battery packs

- Quick reference instructions for responders

An AED in the workplace increases survival chances during cardiac arrest when used promptly with CPR.

Custom and Specialty Kits

Some manufacturing facilities face unique hazards, requiring specialized kits:

- Burn kits for welding or chemical exposure

- Trauma kits for machinery-related injuries

- Vehicle kits for transport and logistics operations

- Infection control supplies for biohazard risk environments

At

Rapid Rescue Kits, we specialize in traditional rescue kits that are adaptable to industrial needs. Our kits are organized to help responders find what they need quickly under stress.

Emergency Preparedness in Manufacturing

Regular Inspection and Maintenance

A first aid kit is only effective if supplies are current and accessible. Outdated items or missing supplies can hinder response.

Best practices:

- Inspect kits monthly

- Replace expired medications or sterile items

- Restock immediately after use

- Keep a maintenance log

Employee Training and Emergency Response

Supplies alone are not enough. Employees need training to respond effectively.

- CPR and AED training should be mandatory for safety teams

- Scenario-based drills help employees respond faster under pressure

- Encourage cross-training so multiple people know how to use equipment

Trained employees reduce panic and confusion during emergencies.

Smart Kits and Technology

Some modern industrial first aid kits include integrated technology. Examples include visual instructions or digital guides built into AEDs that coach responders through CPR.

While not mandatory, these features can assist untrained employees in providing life-saving care while waiting for emergency services.

Choosing the Right Kit for Your Manufacturing Plant

Selecting the right kit starts with a hazard assessment. Consider:

- Size of your facility

- Number of employees per shift

- Common hazards and injury types

- Distance to local emergency services

Decision guide:

- Small workshops with limited risks: ANSI Class A with added CPR mask

- Medium to large facilities with machinery and chemicals: ANSI Class B with AED integration

- High-risk operations with multiple hazards: Custom kits plus dedicated AED packages

Rapid Rescue Kits offers traditional emergency response kits designed to address multiple industrial needs. Compact, durable, and well-organized, our kits provide essential tools for bleeding control, immobilization, CPR, and shock management.

Common Gaps in Existing Competitor Content

When researching industrial first aid kits, many guides fail to address key areas:

- Training and maintenance practices are often overlooked

- CPR and AED supplies are treated separately instead of integrated into one kit

- Few sources highlight the value of smart kits with guided technology

- Selection advice is vague without a structured decision process

This is where Rapid Rescue Kits adds value. We focus on practical, actionable readiness strategies, not just supply lists.

Best Practices for Implementation in Manufacturing

A structured approach ensures effective emergency preparedness.

- Conduct a hazard assessment of your facility

- Select the right kit class and include CPR and AED supplies

- Install kits in visible, accessible locations with signage

- Train employees and run regular emergency drills

- Review logs, restock, and improve readiness over time

These steps help ensure compliance, readiness, and improved safety outcomes.

Workplace Safety Supplies and Employee Confidence

Preparedness is not only about compliance. It builds trust. Employees who see that their company invests in proper first aid supplies and training feel more valued and secure. This contributes to stronger morale and lower turnover.

Safety supplies should be integrated into broader emergency preparedness plans. Aligning with OSHA and ANSI standards supports compliance and strengthens workplace safety culture.

Future of Manufacturing Emergency Preparedness

Looking ahead, industrial first aid will continue to evolve with technology and data.

- AEDs with real-time monitoring and connectivity

- Digital tracking of kit supplies with automated alerts for restocking

- More compact trauma solutions for fast deployment

Manufacturers that adopt advanced kits will be better positioned to manage risks and protect their workforce.

Rapid Rescue Kits for Manufacturing Safety

At Rapid Rescue Kits, we design traditional emergency response kits that are reliable, organized, and ready when needed.

Our Traditional Rapid Rescue Kit includes:

- Bleeding control tools like tourniquets and gauze

- Immobilization equipment such as splints and wraps

- CPR mask in a hard case

- Shock management supplies including emergency blankets

- Multi-use tools such as trauma shears, gloves, and sterile water

We build kits that support effective emergency response while being compact and durable for industrial use.

For manufacturing companies, investing in the right first aid kits with CPR and AED equipment is not optional. It is a proactive step toward protecting employees, meeting safety standards, and creating a prepared workforce.

Rapid Rescue Kits remains committed to supporting industries with tools that help stabilize injuries until medical professionals arrive.